- Angle Tolerances For Iso 2768 M General Tolerance

- Angle Tolerances For Iso 2768 M K

- Din Iso 2768 M Tolerance

- Din Iso 2768 M Tolerances

- Angle Tolerances For Iso 2768 Metal

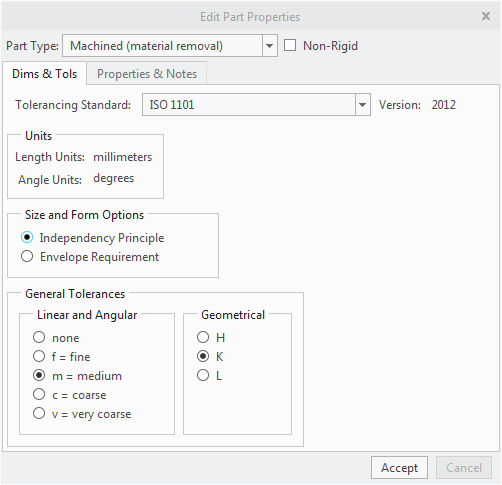

General tolerance ISO 2768 does not specify where to use these tolerance. As per design requirement and manufacturing capability tolerance class is defined. For example: For sheet metal parts ISO 27 68 – mk is used. And for machined components ISO 27 68 – fh can be used. In above example “m” and “k” has defined the tolerance class.

Designation

Division of basic dimension 0.5 (1)

Over 3

Over 6

Over

Over

Over

Over

Over

up to 3

up to 6

up to

30 up

120 up

400 up

1000

2000

30

to 120

to 400

to

up to

up to

1000

2000

4000

Description

Permissible deviations f

fine

0.05

0.05

0.1

0.15

0.2

0.3

0.5

-

m

medium

0.1

0.1

0.2

0.3

0.5

0.8

1.2

2

c

coarse

0.2

0.3

0.5

0.8

1.2

2

3

4

v

very coarse

-

0.5

1

1.5

2.5

4

6

8

Note (1) :

For basic dimensions below 0.5 mm, the deviations shall be indicated adjacent to the relevant basic dimension(s).

Table 2. Permissible deviations for linear dimensions of chamfered parts (Rounding of corner and chamfered dimension) Unit : mm Tolerance class

Division of basic dimension

Designation

Description

0.5 (1)

Over 3

up to 3

up to 6

Over 6

Permissible deviations

Note (1) :

f

fine

m

medium

c

coarse

v

very coarse

0.2

0.5

1

0.4

1

2

For basic dimensions below 0.5 mm, the deviations shall be indicated adjacent to the relevant basic dimension(s).

Table 3. Permissible deviations for angular deviations

Tolerance class

Deviation of length (unit : mm) of the shorter side of the angle concerned Up to 10

Designation

Description

Over 10

Over 50

Over 120

up to 50

up to 120

up to 400

Over 400

Permissible deviations f

fine

m

medium

c v

1°

30c

20c

10c

5c

coarse

1°30c

1°

30c

15c

10c

very coarse

3°

2°

1°

30c

20c

Table 4. General tolerances on straightness and flatness Unit : mm Straightness and flatness tolerances for ranges of nominal lengths Tolerance

Up to 10

class

Over 10

Over 30

Over 100

Over 300

Over 1000

up to 30

up to 100

up to 300

up to 1000

up to 3000

General tolerances on straightness and flatness H

0.02

0.05

0.1

0.2

0.3

0.4

K

0.05

0.1

0.2

0.4

0.6

0.8

L

0.1

0.2

0.4

0.8

1.2

1.6

Table 5. General tolerances on perpendicularity Unit : mm Perpendicularity tolerances for ranges of nominal lengths of the shorter side Tolerance class

Up to 100

Over 100

Over 300

Over 1000

up to 300

up to 1000

up to 3000

General tolerances on perpendicularity H

0.2

0.3

0.4

0.5

K

0.4

0.6

0.8

1

L

0.6

1

1.5

2

Table 6. General tolerances on symmetry Unit : mm Symmetry tolerances for ranges of nominal length Tolerance

Up to 100

class

Over 100

Over 300

Over 1000

up to 300

up to 1000

up to 3000

General tolerances on symmetry H

0.5

K L

0.6 0.6

1

0.8

1

1.5

2

Table 7. General tolerances on circular run-out Unit : mm Tolerance class

Circular run-out tolerance

H

0.1

K

0.2

L

0.5

Angle Tolerances For Iso 2768 M General Tolerance

This standard was last reviewed and confirmed in 2017. Therefore this version remains current.

Abstract Preview

This part is intended to simplify drawing indications and specifies general tolerances in four tolerance classes. It applies to the dimensions of workpieces that are produced by metal removal or are formed from sheet metal. It contains three tables and an informative annex with regard to concepts behind general tolerancing of dimensions.

General information

- Publication date : 1989-11

- Number of pages : 3

- :Dimensional and geometrical product specifications and verification

- ICS :

- Limits and fits

Buy this standard

- CHF38

Life cycle

Angle Tolerances For Iso 2768 M K

A standard is reviewed every 5 years

- 20

- 30

- 40Enquiry

- 50

- 60Publication

- 90.93Review

Revisions / Corrigenda

Din Iso 2768 M Tolerance

- Previously

ISO 2768:1973 - Now confirmed

ISO 2768-1:1989

Din Iso 2768 M Tolerances

Opening hours:

Monday to Friday - 09:00-12:00, 14:00-17:00 (UTC+1)

Angle Tolerances For Iso 2768 Metal

Keep up to date with ISO

Sign up to our newsletter for the latest news, views and product information